A research team led by Dr. Jong-Woo Kim and Dr. Da-Seul Shin at the Korea Institute of Materials Science (KIMS) has achieved a significant milestone by developing Korea’s first full-cycle magnetic cooling technology. This innovation promises to address environmental challenges posed by traditional gas-based refrigeration systems while introducing high-efficiency cooling solutions.

Magnetic cooling technology operates without gas refrigerants, utilizing the magnetocaloric effect, where the temperature of a material changes when subjected to an external magnetic field. Despite its potential, commercialization has been hampered by high production costs and reliance on rare-earth elements, which raises concerns about competitiveness in the market. The team overcame these hurdles by synthesizing various magnetocaloric materials, including lanthanum (La)-based and manganese (Mn)-based alloys.

Advancements in Material Synthesis and Production

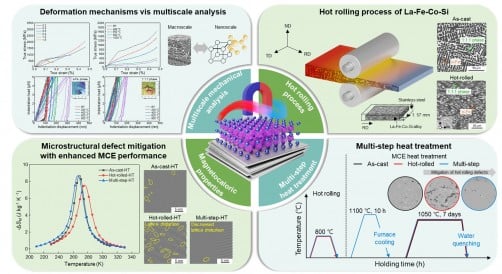

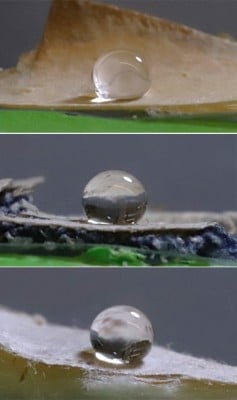

Through advanced fabrication techniques such as hot rolling, cold drawing, and micro-channel machining, the researchers successfully created large-area La-based thin sheets measuring 0.5 mm in thickness and Gd-based fine wires with a diameter of 1.0 mm. These components demonstrated exceptional performance and efficiency, positioning them at the forefront of global standards.

The research team also focused on enhancing the cooling performance of non-rare-earth Mn-based materials by controlling thermal hysteresis and adjusting magnetic anisotropy. They developed Korea’s first measurement system capable of directly monitoring adiabatic temperature changes in magnetic cooling materials. This system allows for quantitative verification of the properties, enabling the optimization of materials and components for practical applications.

As global regulations on refrigerants tighten, particularly under the Kigali Amendment to the Montreal Protocol, which mandates a complete ban on major gas refrigerants by 2030, the need for alternative cooling technologies has never been more urgent. The emergence of magnetic cooling technology aligns with decarbonization policies and climate change initiatives, indicating its potential as a core solution in the cooling market.

Future Prospects and Industry Impact

Research conducted in technologically advanced countries, such as Germany, shows that magnetic cooling systems can achieve coefficients of performance (COP) that surpass those of conventional methods. This trend highlights the growing viability of magnetic refrigeration technology on a global scale.

Dr. Jong-Woo Kim emphasized the transformative potential of this technology, stating, “Once commercialized, this technology will overcome the limitations of conventional gas-based cooling systems and provide an eco-friendly and stable cooling solution.” Similarly, Senior Researcher Dr. Da-Seul Shin highlighted the project’s goal to advance magnetocaloric technology while establishing a domestic industrial infrastructure and expanding into the global market.

The research is part of a broader initiative funded by the Basic Research Program of KIMS and the Creative Convergence Research Program of the National Research Council of Science and Technology (NST). The results were published in May 2025 in the prestigious academic journal Rare Metals, with Ph.D. candidate Sun-Young Yang listed as the first author. The team has also filed for a patent related to the magnetic cooling evaluation system in both Korea and the United States.

The development of this innovative technology positions KIMS as a leader in the field, contributing significantly to both national and global efforts to create sustainable cooling solutions.