A recent study led by researchers at Beihang University has introduced a new, cost-effective material capable of efficiently removing heavy metal complexes from water. The modified biochar, known as ferromanganese oxide-modified biochar (FMBC-600), achieved a remarkable 99.5% copper removal rate and a total organic carbon reduction of 92.6%. This advancement, detailed in the journal Biochar X on October 14, 2025, addresses a critical gap in conventional wastewater treatment methods, which often overlook stable metal complexes prevalent in industrial and municipal effluents.

Conventional treatment techniques primarily target free metal ions, neglecting metal complexes that are often bound with organic agents such as citric acid. These complexes resist degradation and can lead to long-term ecological and health risks. Copper–citrate complexes are particularly common in industries like electroplating and textile dyeing, making their effective removal essential. Traditional methods such as precipitation and ion exchange fall short in addressing these stable complexes, highlighting the need for innovative solutions.

The FMBC-600 material was synthesized using impregnation and high-temperature calcination, resulting in a biochar with a rough surface uniformly coated with nanoparticles ranging from 80 to 100 nanometers. The research team, led by Wenhong Fan, systematically characterized the biochar’s structure and its performance in removing copper citrate complexes from water.

Enhanced Adsorption Mechanism

Characterization techniques, including field emission scanning electron microscopy (FE-SEM) and energy dispersive spectroscopy (EDS), confirmed the successful incorporation of iron (Fe) and manganese (Mn) into the biochar structure. Additional analyses through Fourier-transform infrared spectroscopy (FTIR) and X-ray diffraction (XRD) revealed the presence of various functional groups as well as crystalline phases of Mn3O4 and (FeO)0.099(MnO)0.901. These modifications significantly enhanced the biochar’s adsorption capabilities.

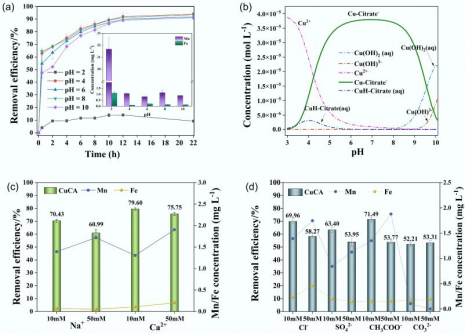

The study found that under optimal conditions—specifically, a Fe:Mn ratio of 1:4, a manganese concentration of 0.03 M, and pyrolysis at 600 °C—the FMBC-600 exhibited rapid adsorption, achieving 99.5% copper removal within just 30 minutes. This material maintained stability across a pH range of 4 to 10, demonstrating resilience even in the presence of competing ions such as sodium (Na+), calcium (Ca2+), chloride (Cl−), and sulfate (SO42−).

Kinetic modeling indicated that the adsorption process primarily followed a pseudo-second-order equation, suggesting that chemisorption is the dominant mechanism. The Freundlich isotherm model further described the heterogeneous multilayer adsorption, which is enhanced at elevated temperatures.

Scalability and Environmental Impact

The research also included regeneration tests, which showed that FMBC-600 retained about 80% of its adsorption efficiency after two cycles. This level of stability and reusability makes the material a viable option for large-scale applications in wastewater treatment, particularly in sectors such as electroplating, dyeing, and chemical manufacturing.

In addition to wastewater management, the technology could potentially be adapted for soil remediation, aiding in the reduction of heavy metal accumulation in agricultural lands. The FMBC-600 outperforms conventional adsorbents in terms of selectivity, stability, and reusability, making it a promising solution for real-world applications where water chemistry is complex and variable.

The implications of this research are significant, as integrating ferromanganese oxide-modified biochar into existing wastewater treatment frameworks could substantially reduce metal contamination. This advancement aligns with global efforts to ensure clean water access and promote sustainability.

Funding for this study was provided by various organizations, including the National Natural Science Foundation of China and the Scientific Research Project of Inner Mongolia University of Technology. The promising results of this research highlight the potential of innovative materials in addressing persistent environmental challenges.