A research team from the National Institute for Materials Science (NIMS) has developed an innovative automated system that can generate extensive datasets from a single sample of a superalloy used in aircraft engines. This high-throughput system produced a comprehensive experimental dataset in just 13 days, containing several thousand records that detail processing conditions, microstructural features, and yield strengths. The rapid generation of such data could revolutionize data-driven materials design.

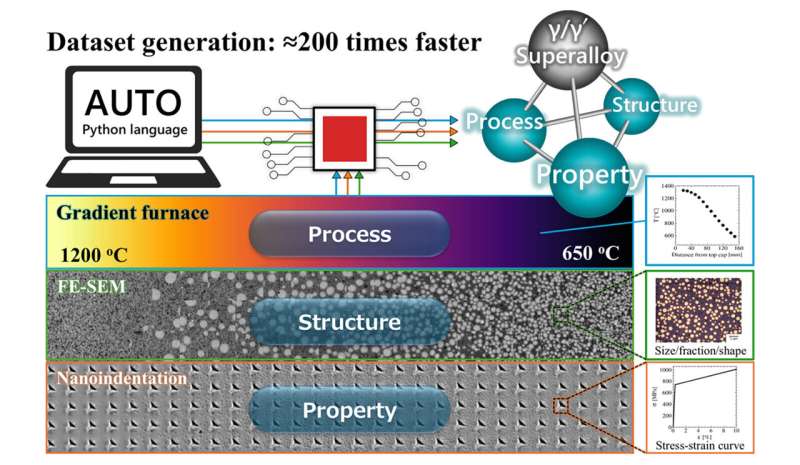

The research, published in Materials & Design, highlights the system’s efficiency, which operates over 200 times faster than conventional methods. This advancement is particularly significant in the field of materials science, where high-precision data is crucial for understanding material mechanisms, formulating theories, and driving innovations.

High-quality Process–Structure–Property datasets are essential for optimizing the processing methods of heat-resistant superalloys. Traditionally, creating these datasets required years of extensive experimental work and significant resource investment, which has impeded the development of high-performance superalloys. The recent development of this automated system addresses those challenges.

The NIMS team focused on a Ni-Co-based superalloy specifically designed for use in aircraft engine turbine disks. By utilizing a gradient temperature furnace, the team thermally treated the superalloy sample across a range of processing temperatures. This method allowed them to map various processing conditions, which included heat treatment temperatures, microstructural information, and mechanical properties such as yield stress.

Measurements of precipitate and yield stress were conducted at different coordinates along the temperature gradient. These assessments were performed using a scanning electron microscope, which was automatically controlled through a Python API, in conjunction with a nanoindenter. The system rapidly evaluated and processed the collected data, yielding a volume of information that traditional methods would have required approximately seven years and three months to generate.

Looking ahead, the NIMS research team plans to extend the application of this automated system to construct databases for various superalloys. The team aims to develop new technologies that acquire high-temperature yield stress and creep data. Additionally, they intend to create multi-component phase diagrams, which are vital for effective materials design, based on the constructed superalloy databases.

Their ultimate goal is to explore new superalloys with desirable properties using data-driven techniques, potentially contributing to the fabrication of heat-resistant superalloys that support efforts toward achieving carbon neutrality.

This research marks a significant step forward in the field of materials science, with implications that could transform the way superalloys are developed and optimized for future applications.

For further information, refer to the study conducted by Thomas Hoefler and colleagues, titled “Automated system for high-throughput process-structure-property dataset generation of structural materials: A γ/γ′ superalloy case study,” published in Materials & Design in 2025.