Graphene, often hailed as a revolutionary material, is known for its exceptional strength, electrical conductivity, and versatility. Despite over a decade of research, many applications of graphene remain confined to laboratory settings. A significant barrier is the difficulty in dissolving graphene in common solvents, which necessitates complex and environmentally damaging functionalization processes. Recently, a team of researchers led by Chamalki Madhusha at Monash University has made strides in addressing this challenge by developing a sustainable method to produce nitrogen-doped graphene nanoplatelets (N-GNPs) using a bio-derived, solvent-free mechanochemical approach.

Challenges in Functionalizing Graphene

While pristine graphene boasts remarkable properties, many advanced applications—such as smart coatings and conductive composites—require chemical modifications to enhance their performance. One prevalent method is nitrogen doping, which improves graphene’s electronic structure and interaction with polymers. Traditional nitrogen-doping techniques, however, often involve toxic precursors, harsh purification steps, and high-temperature processes that generate substantial waste.

These methods, although effective, raise serious concerns regarding their environmental impact. The environmental cost associated with conventional processes is increasingly scrutinized as industries shift their focus towards sustainability.

Mechanochemistry: A Sustainable Alternative

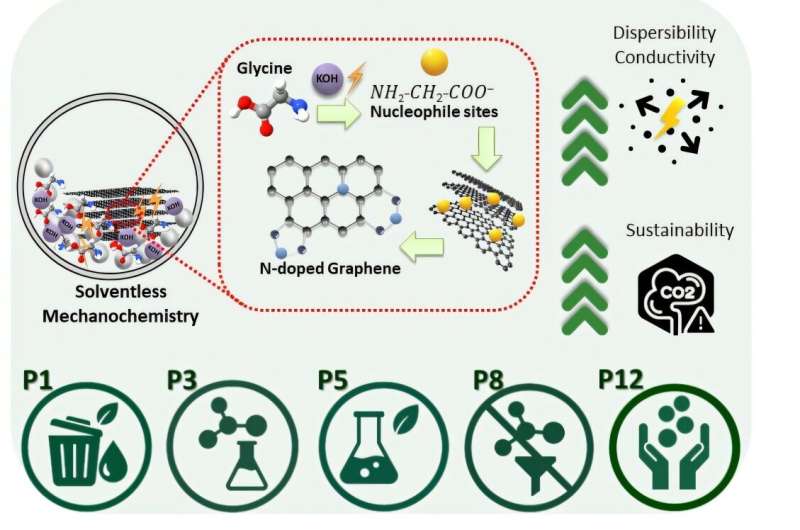

The research team employed mechanochemistry, a method that utilizes mechanical forces like shear and friction to facilitate chemical reactions. This innovative technique has gained traction in green chemistry due to its ability to eliminate solvents and reduce energy consumption.

In their study, published in ACS Sustainable Chemistry & Engineering on December 25, 2025, the researchers employed a ball-milling process to functionalize graphite using amino acids as a nitrogen source under ambient conditions. This approach allowed them to produce N-GNPs without the need for toxic reagents or extensive purification steps. The resulting materials exhibited high electrical conductivity and excellent dispersibility, effectively addressing two significant challenges in graphene processing.

To assess the sustainability of their method, the researchers conducted a thorough evaluation that included both qualitative and quantitative metrics. Their process achieved a remarkable material yield of approximately 80%, which is significant for a solid-state synthesis method. The researchers also noted a considerably lower E-factor, a standard metric in green chemistry that measures waste generation per unit of product.

By eliminating solvents and high-temperature steps, the overall energy consumption of the process was notably reduced, demonstrating that thoughtful process design can enhance the sustainability of advanced materials without sacrificing performance.

The Unique Properties of Nitrogen-Doped Graphene

Nitrogen atoms integrated into the graphene lattice can alter the movement of electrons, enhancing electrical conductivity and chemical reactivity. The N-GNPs produced in this study retained their structural integrity while benefiting from the functional enhancements provided by nitrogen doping. When incorporated into composite systems, these nanoplatelets showed potential to significantly improve electrical, thermal, and mechanical properties.

This innovation is particularly relevant for applications involving self-healing materials. The compatibility of N-GNPs with vitrimers, a class of polymers that combine the durability of thermosets with the reprocessability of thermoplastics, allows for the development of materials that can self-repair when damaged. This capability not only extends the lifespan of products but also aligns with the growing emphasis on sustainability in materials engineering.

Implications for Future Materials Development

While this research centers on graphene, its implications extend to the broader field of advanced materials. Many high-performance materials are still manufactured using processes developed when environmental concerns were less prominent. The mechanochemical, solvent-free strategies introduced in this study highlight the feasibility of rethinking these traditional pathways.

As industries—particularly those focused on electronics, aerospace, and energy storage—continue to prioritize sustainable practices, the insights gained from this research may inform future material design and manufacturing processes.

Looking ahead, Madhusha and her team plan to explore how this green synthesis approach can be adapted for other dopants and composite systems, ultimately aiming to refine and expand sustainable manufacturing practices in the field of advanced materials. As the demand for functional materials grows, the need for environmentally friendly synthesis methods will become increasingly vital in shaping the future of technology.

This research not only represents a significant advancement in the field of nanomaterials but also serves as a model for integrating sustainability into the core of materials innovation.