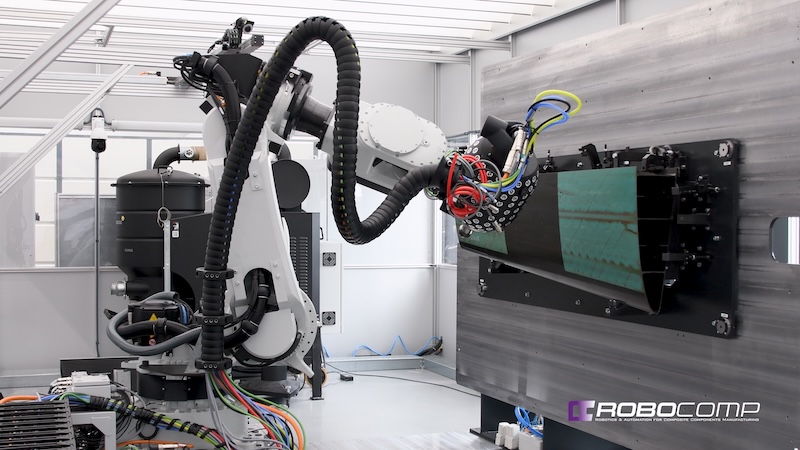

The aerospace industry is taking a significant step towards achieving its goal of net zero emissions by 2050. The technology centre IDEKO has developed a new generation of robotic cells designed to enhance manufacturing flexibility while simultaneously reducing production costs. This innovative approach aims to address the industry’s reliance on heavy, expensive, and inflexible machinery, which is currently hindering progress toward sustainability.

The dual objectives of minimizing emissions and improving competitiveness are critical for the future of aerospace manufacturing. As the sector grapples with increasing environmental regulations and market pressures, the integration of advanced robotic technologies could prove transformative. The newly developed robotic cells are designed to adapt to various production processes, allowing manufacturers to tailor their operations to meet specific demands while significantly cutting down on waste and emissions.

Transforming Manufacturing Processes

The introduction of these robotic systems marks a pivotal shift for the aerospace sector. Traditional manufacturing methods often involve large machines that are not only costly to operate but also inflexible in their application. In contrast, the new robotic cells are compact and versatile, enabling manufacturers to optimize their production lines efficiently. This adaptability is essential in a market that increasingly values both sustainability and rapid response to consumer needs.

According to IDEKO, the adoption of these robotic cells can lead to a reduction in production costs by as much as 30%. This substantial decrease is attributed to lower energy consumption and enhanced operational efficiency. By streamlining manufacturing processes, aerospace companies can allocate resources more effectively, ultimately improving their bottom line while committing to environmental responsibility.

Impact on the Aerospace Industry

The aerospace industry is facing unprecedented challenges as it strives to meet stringent sustainability targets. The need for innovative solutions is more pressing than ever. The new robotic cells developed by IDEKO not only contribute to the industry’s goal of achieving net zero emissions but also enhance its global competitiveness.

With the global aerospace market projected to grow significantly over the next decade, the pressure to innovate and adapt is mounting. The introduction of flexible manufacturing solutions is essential for companies looking to differentiate themselves in a crowded market. By embracing this new technology, manufacturers can position themselves as leaders in both sustainability and efficiency.

As the aerospace sector prepares for a future dominated by environmentally friendly practices, the role of technology in driving these changes cannot be overstated. The advancements brought forth by IDEKO are a testament to the potential for innovation to reshape industries and deliver on critical environmental promises. The journey towards a sustainable aerospace future is well underway, and the implementation of these robotic cells is a crucial milestone in that evolution.